We have a deep-rooted belief that quality must be the focus of the manufacturing process, it can’t be tested in after the fact.

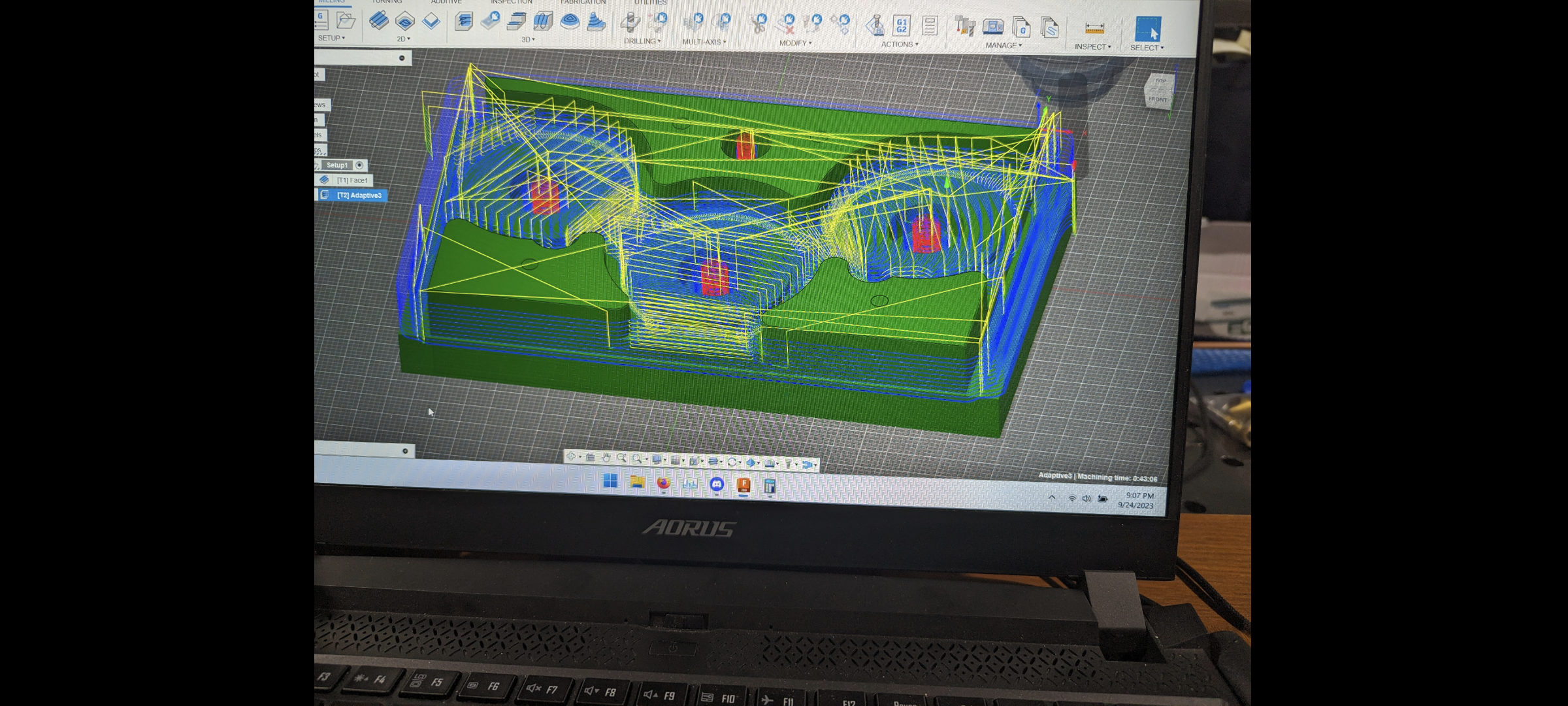

Programming the Machine:

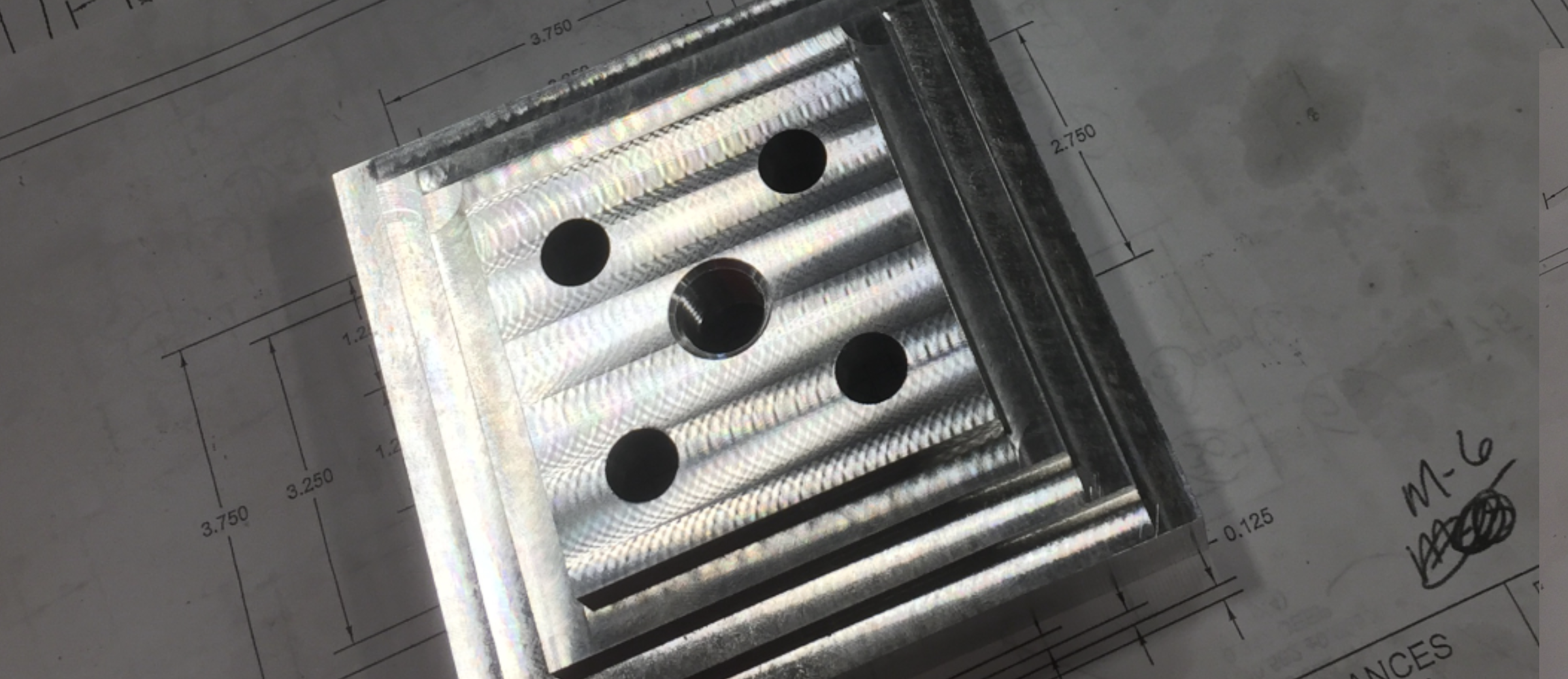

We take your drawings, make a 3D model of your part that is then fed into our toolpathing (CAM) software where we select the most efficient roughing and finishing operations to meet, and surpass, your specifications.

Depending on the complexity of the part and your needs we may hand program the toolpath at the machine. (No 3D modeling is done on my end in this case.)

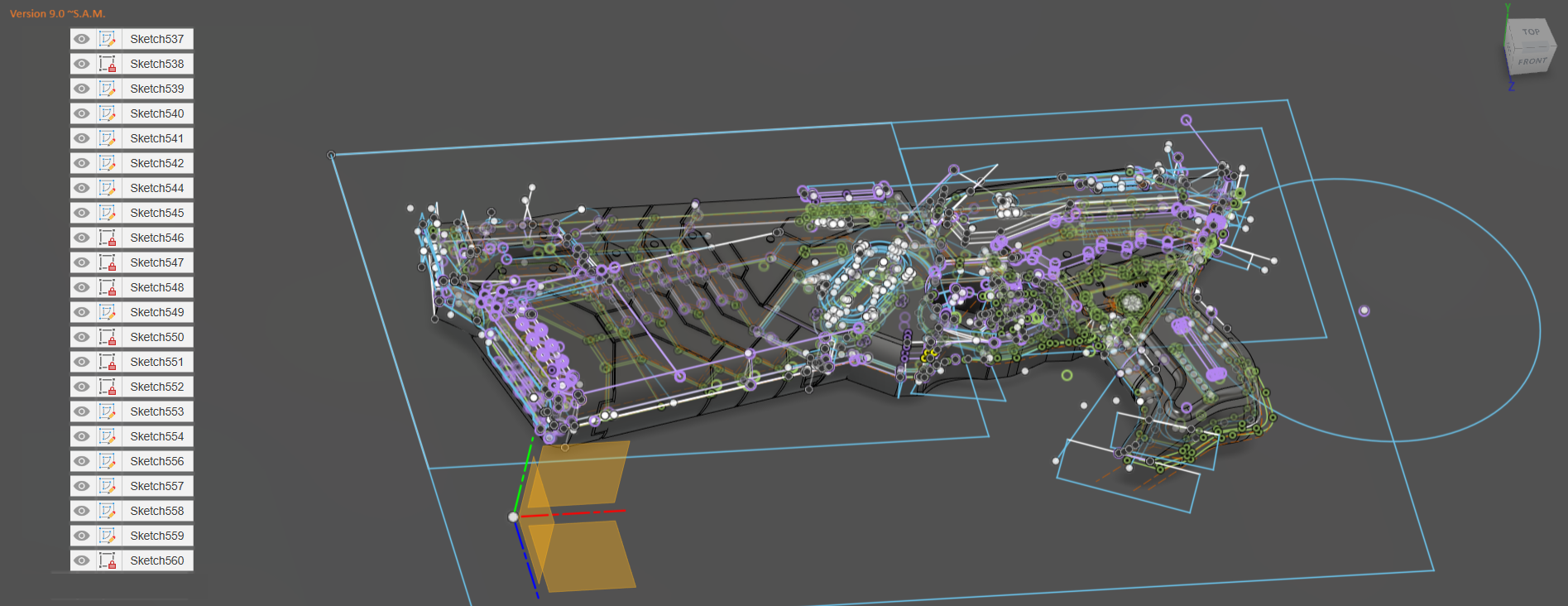

3D Models Made From Your Drawings:

If I need to make a 3D model for my software to tell the machines what to do drawings are never shared, but are kept in case you need more parts in the future.

Any models made are available upon request, but may be subject to our drafting rate.

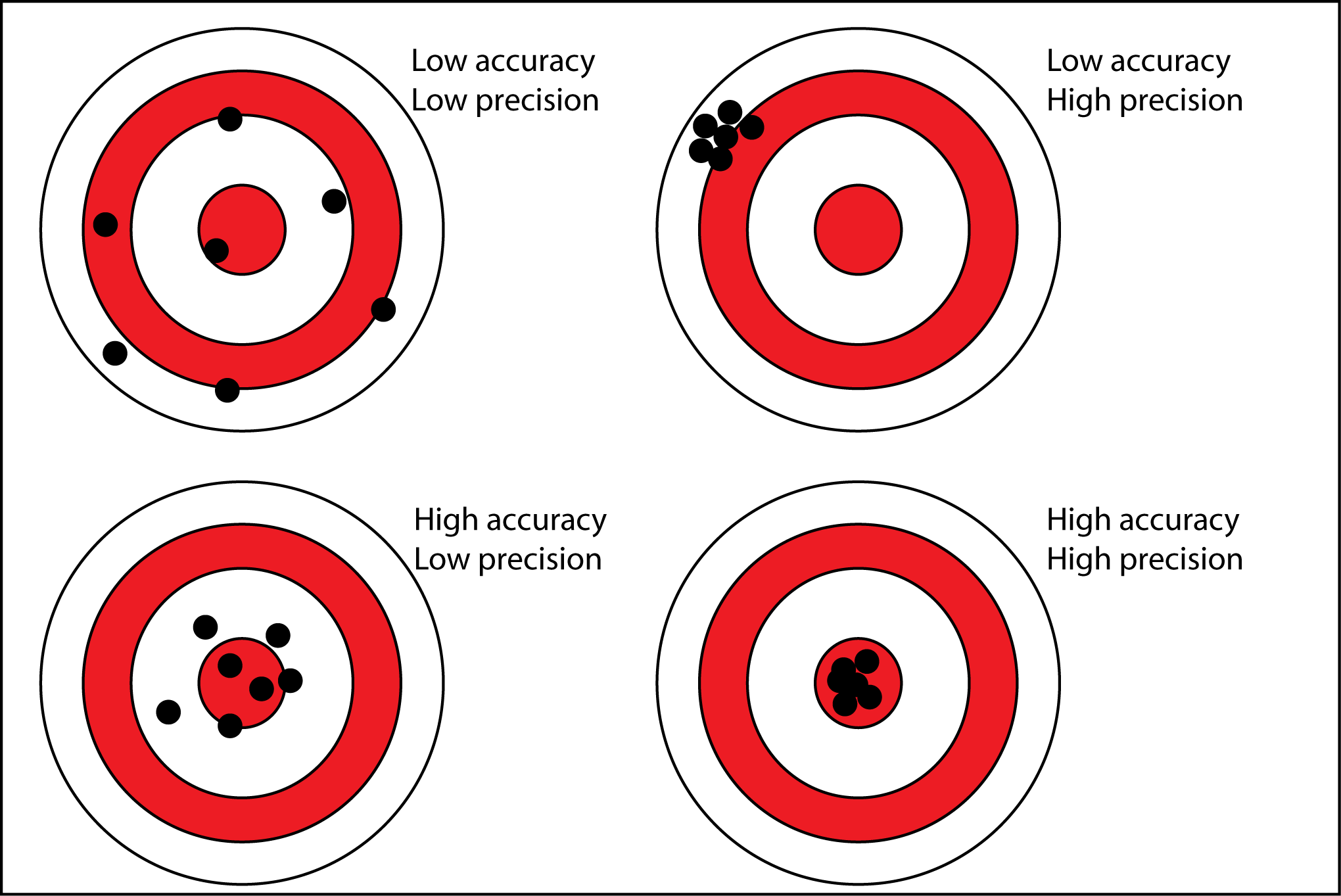

Tolerance Specifications:

Low: +/- .001 inches

General: +/- .005 inches

High: +/- .015 inches

I am not currently working to below a +/- .001 inch tolerance due to limitations of my current measuring capabilities.

I will strive to be both precise (Tight grouping) and accurate (On target) with as little variability between parts as is possible.

{Photo is for reference, calipers aren’t used for final measurement unless the allowed tolerance is fractional}

Sustainability

We strive to have as high a carbon footprint as is possible.

Rapid Prototyping

Trust us to support you through your development phase.

Good, Cheap, Fast

Fast and Good won’t be cheap.

Good and Cheap won’t be fast.

Cheap and Fast won’t be good.

You pay for your specifications.

{Photo is for reference, calipers aren’t used for final measurement unless the allowed tolerance is fractional}